Researching tape can be tough. After all, it’s built on more than a century of breakthroughs in chemistry, physics, rheology, biology, geology, etc. All the -ologies! Then there’s all the different names for tape, such as pressure-sensitive adhesive (PSA), self-adhesive, and self-stick. To simplify the search, here’s a breakdown of adhesive tape types by their five most common structures.

- Single-sided tape

- Single-sided tape on a liner

- Double-sided tape

- Double-sided, high-bond tape

- Adhesive transfer tape

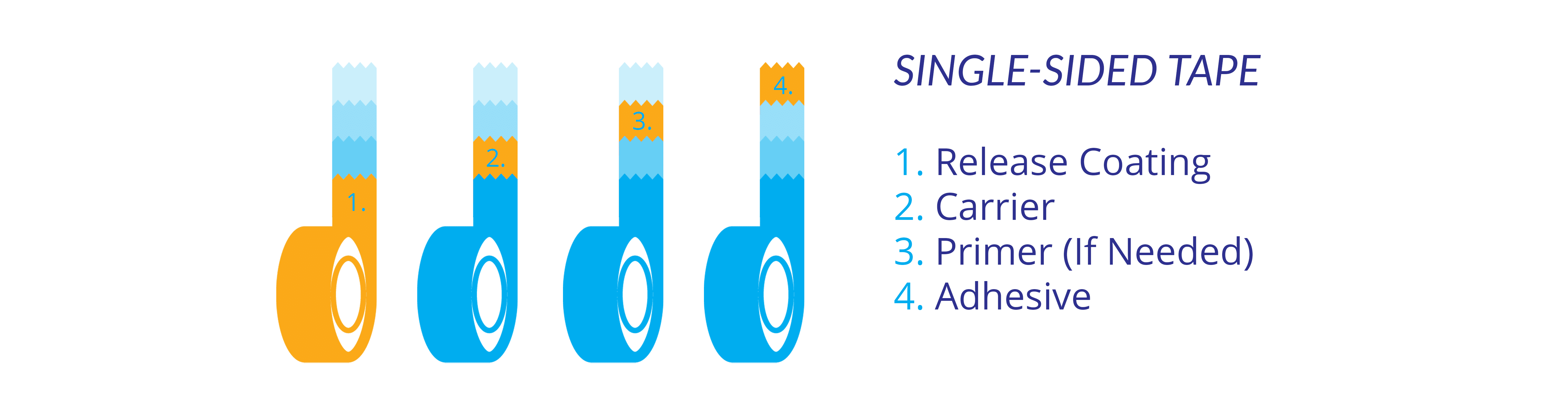

1) Single-Sided Tape

Let’s start with the oldest, most common pressure-sensitive adhesive (PSA). Examples include Scotch™ Tape, masking tape, duct tape, electrical tape, medical tape, and the list goes on. These tapes have one sticky side that unwinds off a roll without a liner.

Tape manufacturers often call them single-coated tapes since it’s their job to coat adhesive to one side of a material. This also applies to why they refer to double-sided tapes as double-coated tapes.

The Construction of Single-Sided Tape

- Release coating: allows tape to unwind without sticking to itself

- Carrier: carries the adhesive and gives tape its structure

- Primer (If Needed): increases the adhesive’s hold to the carrier

- Adhesive: achieves the bond between materials

Release coating: Typically silicone coatings make rolls easier to unwind according to the requirements of your application. Plus, when removing masking tape, release coatings help leave a paint anchorage for clean paint edges.

Carrier: You’ll also see this layer referred to as the backing. That’s because it’s a thin, flexible material that carries the adhesive mass (carrier) and provides structural support (backing). It determines major tape characteristics, even serving as the common name for many PSAs: foam tapes, cloth tapes, filament tapes, foil tapes, etc.

Primer: Increasing the adhesive’s hold to the carrier makes for clean removal and unwinding.

Adhesive: The sticky mass bonding materials together.

Use a lot of masking or surface protection tapes? Custom die-cuts exponentially increase productivity rates, boost your ROI, and slash your labor costs. Send us a free custom quote request, and we’ll quickly let you know if a die-cut masking solution makes sense for your business.

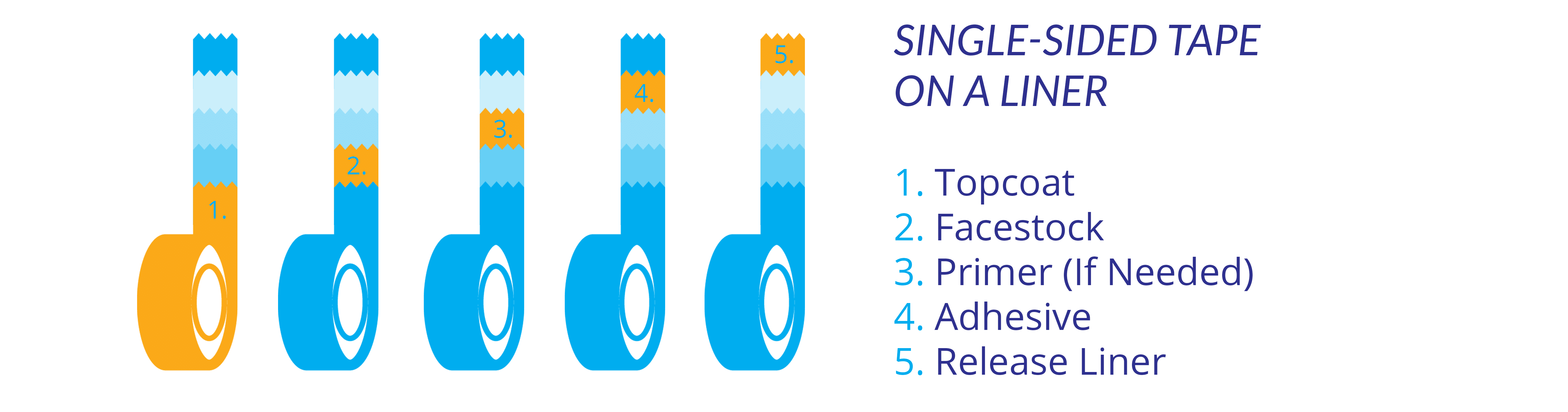

2) Single-Sided Tape on a Liner

Next stop: stickers.

This construction includes a printable side called a facestock and a sticky side on a liner. Examples include labels, decals, graphics, and overlaminates.

The Construction of Single-Sided Tape on a Liner

- Topcoat: protects the ink printed on facestock

- Facestock: carries the adhesive and is printable

- Primer (If Needed)

- Adhesive

- Liner: protects the adhesive until application

Topcoat: Also called the laminate, it increases the ink’s adhesion with both conventional and digital print technologies. Plus, it can modify gloss.

Facestock: In the graphics industry, this layer works like carriers of single-sided and double-sided tapes, with the added perk of being printable.

Primer: When you see terms like anchor coat, barrier coat, sealer coat, or tie coat, they’re all graphics-speak for primer. It prevents the adhesive from migrating into the face material.

Liner: Also called the backing sheet in the label world, it protects the adhesive and supports the facestock during die-cutting, storage, and printing processes. Like a release coating, liners are usually siliconized.

Does your project call for custom labels? We offer our customers access to our design team’s branding and packaging expertise.

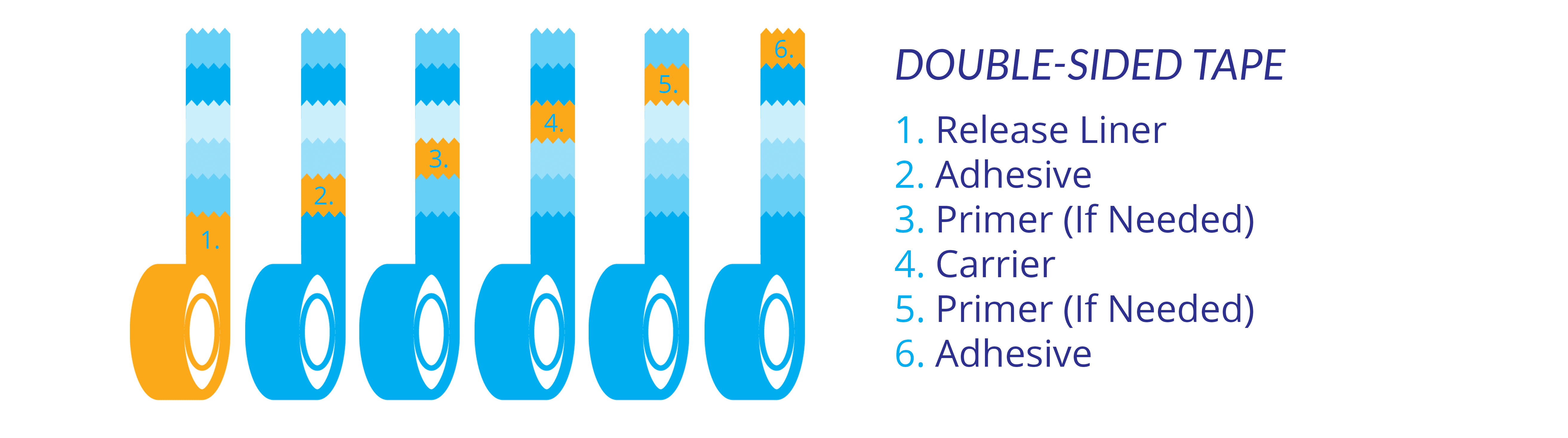

3) Double-Sided Tape

From temporarily holding clothes in place to permanently adhering components onto jet wings, double-sided tape is found in every industry. In fact, it’s often a double-sided tape that drives new market innovations. Just like it sounds, this construction involves adhesive on both sides of the tape. Rolls unwind and protect the top adhesive with a liner.

The Construction of Double-Sided Tape

- Liner

- Adhesive

- Primer (If Needed)

- Carrier

- Primer (If Needed)

- Adhesive

Liner: Liners give tape certain traits such as being tearable by hand, capable of die-cutting, and able to withstand repeated processes. They also offer stability during application and protection during handling and storage.

Primer: Offering the same benefits as stated above, primers strengthen a double-sided tape’s permanent bond performance in mounting applications.

Is a custom double-sided tape the solution you’re looking for? We’re known for our precision and custom capabilities, whether that’s sheeting, die-cutting, tabbing, slitting, you name it. We can invent differential tapes with different adhesives on both sides and even build all new machines if that’s what it takes to make exactly what you need. Take your project to our team of experts.

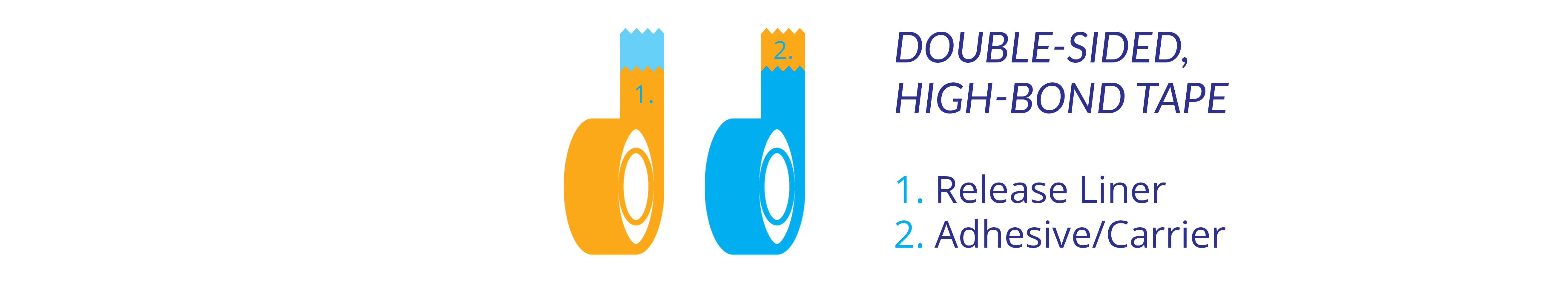

4) Double-Sided, High-Bond Tape

Simply put, high-bond tapes use a hybrid foam adhesive. The difference between general double-sided foam tapes and high-bond tapes boil down to their constructions.

General foam tapes follow the above pattern for double-sided options: adhesive on both sides of a foam carrier. A high-bond tape, on the other hand, uses an adhesive foam that is both the carrier and the adhesive at the same time. This hybrid foam construction beefs up the tape’s performance and is why they’re known as high bonds.

Take for instance, your standard foam tape. It’s possible for the adhesive layer to fail and rip away from the foam. Plus, there’s the chance of the foam itself failing and tearing apart.

But with high-bond options, such as 3M’s VHB™ series or tesa’s ACXplus portfolio, the chances of failure go way down. The adhesive can’t separate from the carrier because the adhesive makes up the carrier. Also, the foam is less likely to tear apart with the adhesive reinforcing it. Case in point, they offer the durability needed for high-stress applications.

The Construction of Double-Sided, High-Bond Tape

- Liner

- Adhesive/Carrier: achieves the bond using a foam adhesive hybrid

Adhesive/Carrier: Instead of three separate layers, it’s a hybrid core that serves as both carrier and adhesive.

Need VHB™ or ACXplus tapes? Our excellent relationships with the world’s leading suppliers allow us to offer some of the best prices, fastest lead times, and free samples. Conveniently add products to a free quote, and request samples today!

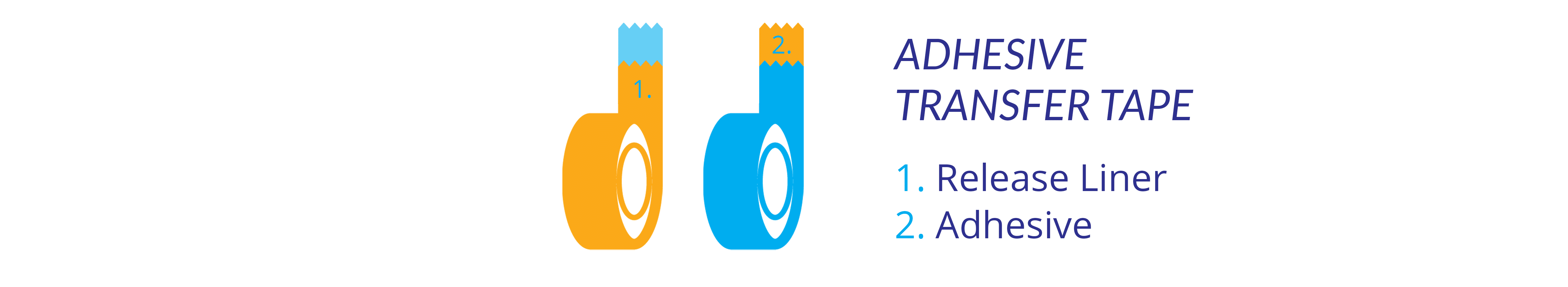

5) Adhesive Transfer Tape

The world’s most versatile tape has many names: transfer adhesive, free film, unsupported pressure-sensitive adhesive (PSA), and transfer tape. Its simple construction makes it easy to customize at a great price point. It’s just an adhesive layer on a liner that doesn’t have a carrier.

Free of the carrier reinforcement, transfer tapes are more conformable than other adhesive tapes. They can also be made to almost any thickness that an application could require.

The Construction of an Adhesive Transfer Tape

- Liner

- Adhesive

In the market for transfer tape? We’re here to help you find exactly what you’re looking for.

Whatever adhesive tape type your project calls for, know that we have you covered. Time and time again, our customers appreciate our dedicated precision in creating the adhesive solution they need. If any part of this industry feels daunting, keep in mind that we ensure constant communication through every step. We really love what we do and look forward to sharing that passion with you soon.