What Makes tesa® Transfer Tapes Live Up to Their Tagline: “Great to Work With” ?

Transfer tape basically has two things going for it:

- It is incredibly cost-effective.

- It is the most versatile tape in the world.

Cost-Effective

By far the biggest advantage in choosing to go with transfer tape is the price.

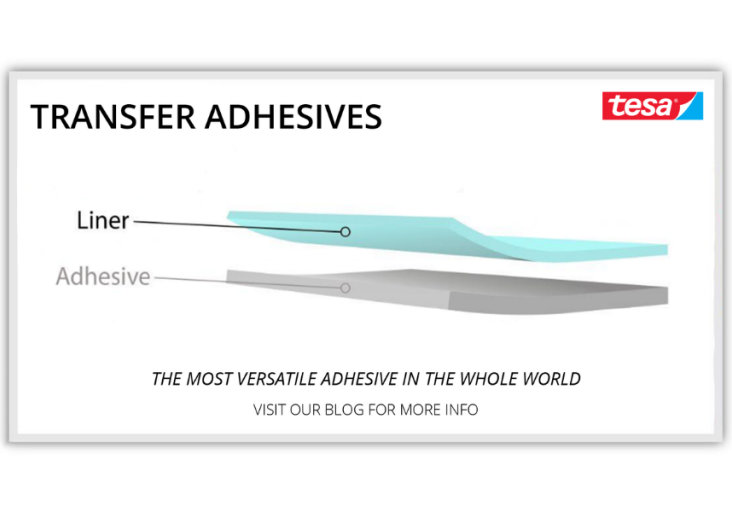

Double-sided tape consists of a layer of liner and two sides of coated adhesives held together by a carrier (or backing).

But transfer tape, on the other hand, has no carrier layer. So all you have to pay for is the liner and the adhesive, and when there’s less to pay for, as is the case for transfer tape, there’s less to pay.

For example, why pay $10 to $12 per square yard for tape when you could use transfer tape at $6 per square yard?

Versatility

Free of a carrier layer, transfer tape has no limitations, becoming fully customizable for the specific needs of any project. It’s transparent, completely conformable to any 3D object, and sticks strong to most any material’s surface.

Because of its versatility, it is used in every industry and is great for low quantity, custom applications:

- Laminates to existing tape, creating a differential

- Combines to other transfer tapes creating a thicker adhesive

- Laminates to a solid carrier creating fully customizable one-sided or double-sided options

Whatever your custom project needs, chances are there is a transfer tape that can do the job.

And at Walker Tape Converting, we can provide any transfer tape customization that you need. Since transfer tape by itself is an unfinished product, we can take the kind that you need and mold it into any finished product for any custom project.

The following are just a few examples of the various tesa® transfer tapes that we can use to meet your custom needs.

High Temperature & High Shear Transfer Tape

These water-based acrylic transfer tapes offer high performance in temperatures ranging from -40° F to 392° F. And tesa® rates them the highest for their static shear resistance, which means they have the best holding power against any pressure that may be pulling down on them.

tesa® 88125

- Good for die cutting

- Great for lamination and converting applications

- 2.5 mils thick

- tesa®’s highest rating for conformability to difficult 3D shapes

- Great for flexible surfaces, NVH (noise, vibration, harshness) and BSR (buzz, squeak, rattle) materials, rubber materials for gaskets, plastics or vinyls for label and tag applications, and decorative fabrics

- Also available as tesa® 88125 PV 13

tesa® 88150

- Good for die cutting

- Great for lamination and converting applications

- 5 mils thick, which makes it even better suited for rough surfaces than 88125

- tesa®’s highest rating for conformability to difficult 3D shapes

- Great for flexible surfaces, NVH (noise, vibration, harshness) and BSR (buzz, squeak, rattle) materials, rubber materials for gaskets, plastics or vinyls for label and tag applications, and decorative fabrics

- Also available as tesa® 88150 PV 13

Low Surface Energy Transfer Tape

Historically, Low Surface Energy (LSE) plastics had to be solvent-welded or attached mechanically, because there weren’t tapes available that could hold to their surfaces very well. Such solvent-welding required hazardous solvents. But recently, there have been breakthroughs in LSE adhesive tapes that allow for strong holds and no longer require the more hazardous processes of the past.

These LSE water-based acrylic transfer tapes hold strong to surfaces like Polyethylene (PE), Polypropylene (PP), Polystyrene (PS), rubber, and medium surface energy plastics like Polyvinyl Chloride (PVC). These breakthroughs in LSE transfer tapes allow them to bond dissimilar materials together, making even more strides in transfer tape’s already impressive customizable capacities.

tesa® 88225

- Good for die cutting

- Great for lamination and converting applications

- 2.5 mils thick

- tesa®’s highest rating for tack and conformability to difficult 3D shapes

- Great for LSE plastics, flexible surfaces, NVH (noise, vibration, harshness) and BSR (buzz, squeak, rattle) materials, rubber materials for gaskets, plastics or vinyls for label and tag applications, and decorative fabrics

tesa® 88250

- Good for die cutting

- Great for lamination and converting applications

- 5 mils thick, which makes it even better suited for rough surfaces than 88225

- tesa®’s highest rating for tack and conformability to difficult 3D shapes

- Great for LSE plastics, flexible surfaces, NVH (noise, vibration, harshness) and BSR (buzz, squeak, rattle) materials, rubber materials for gaskets, plastics or vinyls for label and tag applications, and decorative fabrics

Great to work with, indeed.