Converting Single-Sided Tape into the Best Solution for Your Project

In the tape converting world, we spend a lot of time talking about double-sided tapes and transfer adhesives. But there are an incredible number of advantages to converting single-sided tapes into your project’s solution too.

In the following post, we take you through examples of converting single-sided tape in the following situations:

- Examples that require custom converted single-sided tape

- Examples that may not require it, but seriously benefit from custom single-sided tape

- Plus, a few examples of how we customize single-sided tape to fit your application

Single-Sided Tape Solutions Requiring Customization

Each of these projects mentioned below requires the tapes to perfectly match your product to ensure quality performance. Luckily, as we dive into later, we offer precise die-cutting services to make sure these tapes work perfectly for your purposes.

Single-Sided Foil Tapes

Foil tapes are some of the most capable options out there. As you can see from the below applications, their unique traits make them well suited to take on heavy duty tasks. Some of these abilities include incredible conformability, heat resistance, and the metal foil’s transfer of electricity. All these standout selling points make foil tapes ideal for sealing, shielding, and insulation work.

- Electromagnetic and radio frequency interference (EMI & RFI) shielding

- Heat shielding in ovens

- Heat-sensitive components and light reflectivity in lighting fixtures and in electronics with backlit screens (such as smartphones and tablets)

- Heat reflectivity to protect plastic parts

- Electrically conductive applications

Film Tapes

There are also plenty of reasons why you need the film tapes that you’re working with to be custom fitted to your needs. Probably the most common example is in the protective coverings industry.

Consider the various screen sizes that exist in the electronics market alone. We can die-cut or sheet film tapes to sit exactly over the screens on your smart devices and other electronics.

Single-Sided Foam Tapes

Foam tapes tend to be the tape world’s rock stars. Again, the attention usually goes to double-sided foam options. Yet, there are several scenarios that call for only one sticky side to do the job.

- Vibration damping in speakers and TVs

- Seals to keep out dust in LCD appliances

- Rattle damping pads for battery packs

Single-Sided Medical Tapes

Some of the most apparent die-cut tapes out there are bandages. They make for an easy example that each of us recognize from an early age, much of the time including our favorite cartoon characters or a fun design.

But the need for custom-made medical tape solutions spans the entire medical market:

- Diagnostic testing

- Patient monitoring

- Various dressings for wound care

- Temporarily fixing IVs in place

- Medical device manufacturing

Surprising Single-Sided Tape Solutions that Stand to Benefit from Custom Services

Back to Foil Tape

As we covered above, many foil tapes must be converted to your desired specs. However, there are also applications yet to tap into the benefits of customized solutions.

- HVAC insulation and sealing work along joints and windows

- Fixing wires and cooling coils in place against appliance walls

Often, these kinds of routine jobs use stock rolls available at local hardware stores. But imagine the time and money saved on labor if you had custom rolls slit to the widths that make most sense to your process. The same idea goes for having exact sheets and die-cut parts ready for you to work with.

Masking Tape

From paint work to solar panel manufacturing, masking tapes are everywhere. Like with foil tapes, they’re usually seen everything in the few sizes that your local store has on hand.

By using custom-slit rolls, die-cuts, or sheets of masking tape, you save exponentially more in terms of ROI. This is because masking tape converted to your project eliminates hours of labor time to maximize your production rates.

Here are a handful of examples where you can save big by incorporating custom-converted masking tape:

- Marking or covering walls and floors

- Protecting surfaces from paint, sandblasting, powder coating, dust, scratches, moisture, etc

- Insulating heat and electricity

- Temporary masking in manufacturing processes

- Hole coverings in solar panel production

- Protecting control panels or user interfaces in elevator construction

- Protecting windows on jet airliners during exterior surface treatments

- This list could go on forever

Back to Foam tape

Die-cutting single-sided foam tapes can instantly turn a foam tape into a simple, ROI-boosting gasket solution. It’s truly one of the most genius ways to save money on production costs when your gasket material only needs to stick on one side.

- Sealing against water, air, and dust

- Damping noise, vibration, and harshness (NVR) in transportation markets

- Gasketing filters

- Sound and vibration absorption in consumer goods

- Weather-proofing outdoor lighting fixtures

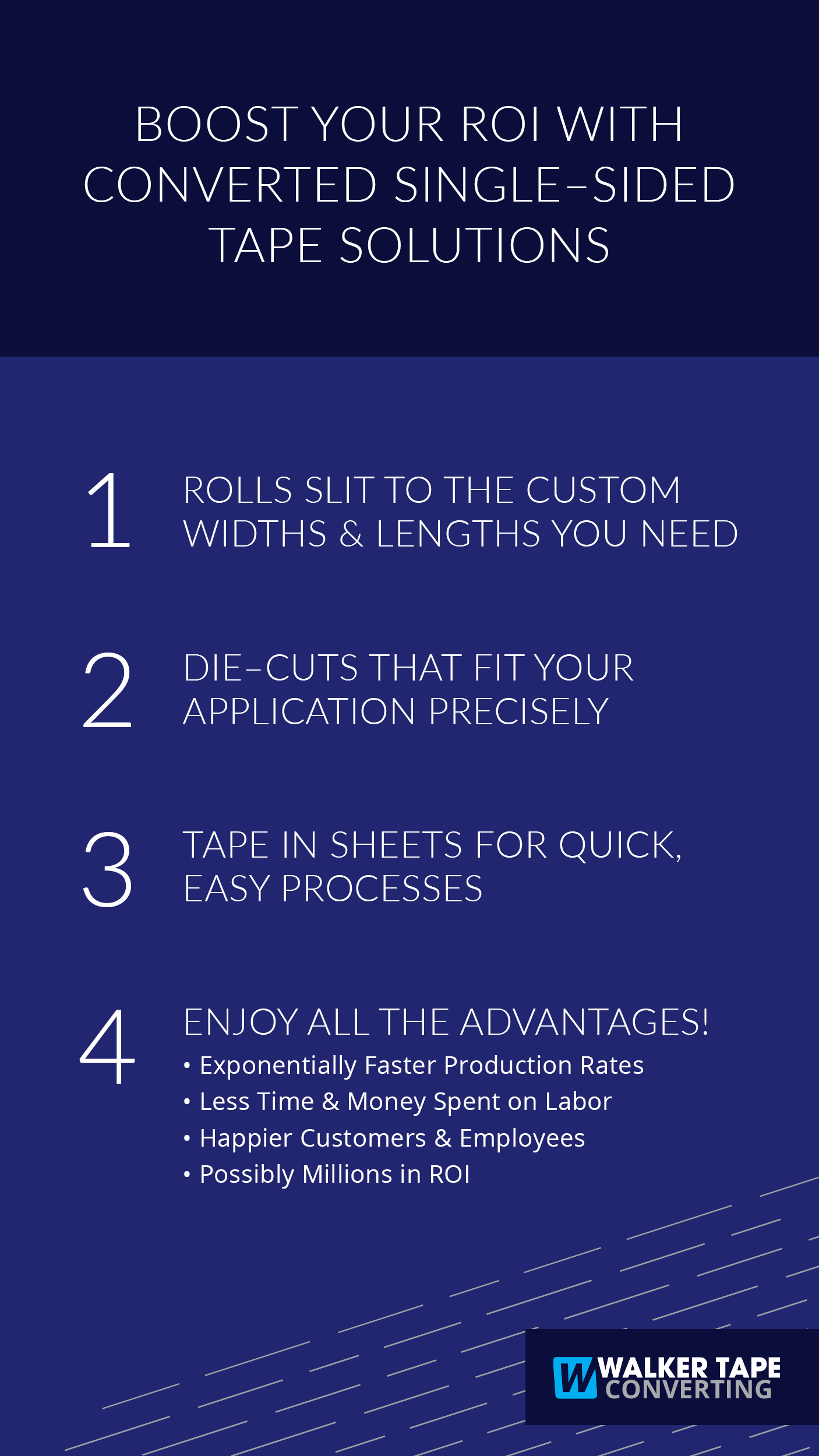

Three Examples of How We Create Custom Single-Sided Tapes to Work for You

Slitting Tape Rolls

Too often, we think of rolls of tape as being limited to the widths and lengths we find at the store. However, what happens when these stock widths are too wide or aren’t quite wide enough for your application? Also, what about the constant need to restock and replace rolls because your quantities needed are much longer than the lengths available?

Our custom roll-slitting capabilities solve all the above situations. We provide you and your team rolls of your go-to tape at the lengths and widths that make the most sense for your process. Our state-of-the-art slitting technology gives you efficiencies and precision that are rarely seen among other converters.

Working with us eliminates time spent going back and forth to get more rolls. We also provide roll solutions that cut out the extra time masking something three times over with exactly-to-spec wider options.

Ready to get jobs done faster than ever? Send us a free quote request for custom-slit rolls of your favorite tapes.

Die-Cutting Tape

Our custom die-cutting abilities can save you hundreds of thousands in the short-term and millions over the long-term. Regardless of the tape type, we can provide it to you in the custom shapes that send your productivity rates through the roof.

We’re transparent about tooling costs. We do this because we want you to have peace of mind while learning how good die-cut solutions are for your business. But even simpler than that, we offer you the best custom services because we’re right there with you investing in your success.

Are you looking for custom tape solutions? Contact one of our experts today, and we can get things rolling for you. Even if you’ve been told before that something is impossible, we’ve been known to invent new machines just to meet the needs of our customers.

Sheeting Tape

In several cases, it makes more sense to work with a sheet of tape rather than a roll. Examples include the temporary hole covering for solar panels and masking solutions that need to be wide enough to cover interfaces. In addition to those, sheeting makes the most sense if your process includes wider, flat layers of material that need to be bonded.

Like our custom slitting and die-cutting services, tape sheeting makes your application easier and faster than ever. We’ve combined our machine-building knowhow with the leading manufacturing experts to customize our in-house sheeting technology. It allows us to sheet any tape you need in a wide range of different sizes with remarkable efficiency.

Could sheeting be the solution to your project? Request a free custom quote from us today!