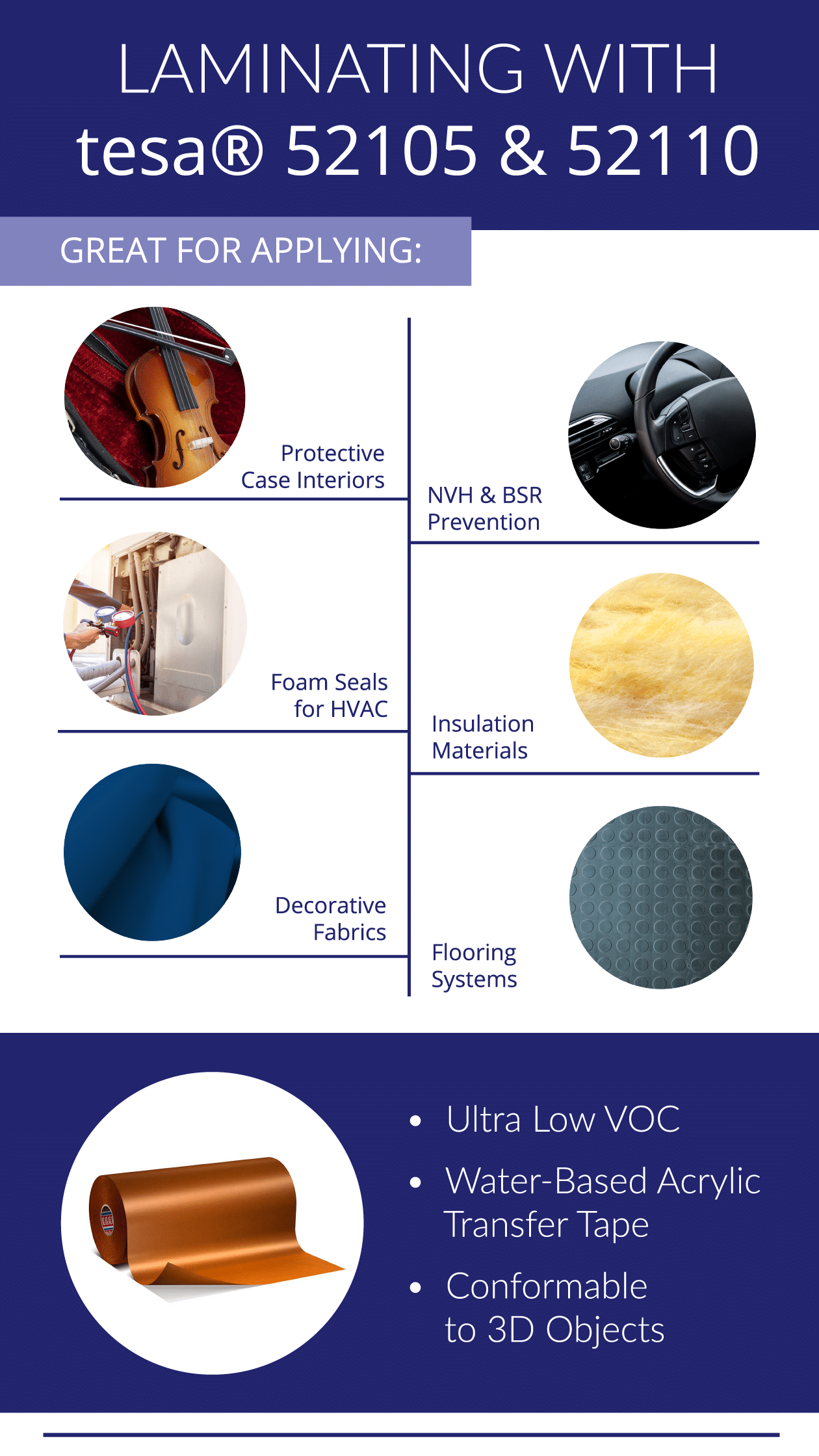

tesa® Water-Based Transfer Tapes: Great to Laminate With

When it comes to tesa’s water-based transfer tapes, we’re hooked.

We’ve focused before on what makes their water-based adhesive a healthier, more sustainable option. Plus, we’ve gone into how versatile they are and how they live up to tesa’s tagline of being “great to work with.”

For this blog piece, though, we’re showing how they’re great to laminate with.

First Off, What Is Lamination?

When you hear lamination, think layers. In tape terms, lamination is simply sticking layers together with adhesive.

Consider, for example, the DIY trick of laminating paper with packing tape. We take the paper layer and stick the tape’s plastic layer on top.

So, when we hear something like foam lamination, it’s still simply referring to sticking layers together with tape. With this in mind, we can understand foam lamination to mean a few different things.

- Sticking multiple layers of foam together

- Sticking foam to layers of different materials

- Simply adding a tape layer to foam

The Perks of Using Water-Based tesa® Transfer Tapes for Laminating

tesa has a lot of great transfer tapes to choose from, and each option has its own specific benefits. However, to keep this blog post simple and consistent, we refer to tesa® 52105 Ultra Low VOC. This allows us to see one transfer tape’s particular benefits and some general perks to using tesa’s water-based transfer tapes.

We include the specs on this tape and its thicker twin, tesa® 52110 Ultra Low VOC, at the end. But for now, let’s dive into the benefits of laminating with tesa’s transfer tapes.

Low VOC: Volatile organic compounds (VOCs) are ingredients that evaporate at room temperature and pollute the air. Since tesa makes transfer tapes with water-based adhesives, they release hardly any VOCs at all. This makes them the healthier choice to work with, especially for laminating applications in vehicle interiors.

For example, tesa® 52105 is a go-to for laminating in automotive partly due to its low VOC rating. It’s so low, in fact, that it avoids fogging from VOC evaporation on the inside of windshields. Besides being low VOC, it also improves the drive experience, preventing issues of noise, vibration, and harshness (NVH), and buzz, squeak, and rattle (BSR).

Conformability: A tape’s ability to follow a material’s shape is vital in laminating to 3D objects, curved angles, or uneven surfaces. tesa’s water-based transfer tapes are highly conformable. Their adhesive layer is completely flexible to stick to even the trickiest shapes.

Excellent Bond to Challenging Surfaces: tesa’s transfer tapes hold reliably to surfaces with challenging textures. Their tesa® 52105, for instance, offers a strong immediate bond to the following materials:

- Composites (recycled materials)

- Hard-to-bond plastics (polypropylene)

- Foams

- Fabrics (felt, fleece, silk)

Easy to Die-Cut: If you need to laminate tape to custom shapes, then seriously consider tesa’s transfer options. Businesses who take advantage of our custom die-cut capabilities see yearly savings in the six figures. An essential part of those savings comes from the quality of the transfer tapes we use.

For decades of die-cutting projects, we’ve turned time and time again to tesa’s dependable line of transfer tapes.

Have a project that calls for sticking tape on unique shapes? Shoot us a free custom quote request, and we can find the perfect tesa transfer tape to do the job.

Consumer Industries: Sticking tesa® Transfer Tapes Inside Your Protective Cases, Safes, & Scrapbooks

So far, we’ve mainly focused on how good tesa transfer tapes are for the automotive market. But really, you find these transfer tapes offering their laminating benefits to every industry.

Keeping with our example, consumer industries are discovering how well tesa® 52105 sticks to the surfaces mentioned above. They use it to laminate the interiors of protective cases with foams and fabrics. Some examples include the following:

- Cases for musical instruments, electronics, jewelry, guns, etc

- Safes and vaults

- Decorative fabrics in the scrapbook industry

Construction Industries: Sticking tesa® Transfer Tapes to Your Insulation & HVAC Seals

tesa’s transfer options help insulate and seal our structures in the construction industry. Below are a few examples of tesa® 52105 at work.

- Fabric liners to insulation

- Foam insulation

- Foam seals in heating, ventilation, and air conditioning (HVAC)

Aerospace Industries: Sticking tesa® Transfer Tapes to Your Flooring Solutions

When you first step onto an airplane, you’re likely standing on a tesa transfer tape.

The aerospace industry leans on tesa® 52105 to laminate their non-textile flooring materials together, such as rubber coin floors at airplane entryways.

tesa® 52105 & 52110

Now to the example we’ve referred to throughout this blog: tesa® 52105 is a go-to for automotive projects. Even in the product description, tesa describes it as a “water-based transfer tape for lamination applications in automotive interior[s].”

But as we’ve highlighted, tesa® 52105’s conformability and bond strength to challenging surfaces make it a great laminating choice for various industries. Its other version, the tesa® 52110, features the same great benefits. It’s simply thicker, making it better suited for rough surfaces.

Features

- Adhesive: Water-based acrylic

- tesa® 52105 Thickness w/o Liner: 2 mil

- tesa® 52110 Thickness w/o Liner: 4 mil

- Adhesive Color: Transparent

- Liner: Glassine

- Liner Color: Yellow

- Surfaces: Low Surface Energy & High Surface Energy

- Best Suited for Rough Surfaces: tesa® 52110

- Temperature Resistance: -40°F to 356°F

- Initial Adhesion to Steel: 118.8 oz/in

- Initial Adhesion to ABS (automotive plastics): 105.1 oz/in

- Initial Adhesion to Polycarbonate: 100.5 oz/in

- Initial Adhesion to Polyester: 105.1 oz/in

- Initial Adhesion to Polypropylene: 86.8 oz/in

- Suitable for Die-Cutting

- Low VOC

- Excellent Fogging Performance

- High Initial Bond Strength

- Great Conformability

Lamination Applications

- Insulation Materials

- NVH & BSR Prevention

- Decorative Fabrics

- Protective Foam Interiors & Seals

- Flooring Solutions

Conveniently add these laminating options to a free quote request, and check out more of tesa’s fantastic transfer tapes today.