Here on the Walker Tape Converting blog, we’ve talked about a lot of different kinds of tape. But there is none quite as tough as those found in the 3M™ General Industrial 300MP Adhesive Family.

This family consists of nothing but double-sided (or transfer), acrylic-based tapes that are designed for hard-to-bond textures and adverse conditions.

If you’re looking for good, strong tapes that can handle just about anything, they could be exactly what you need for your next project. So, let’s go over which tapes are in this family, what makes them so great, and how you can use them.

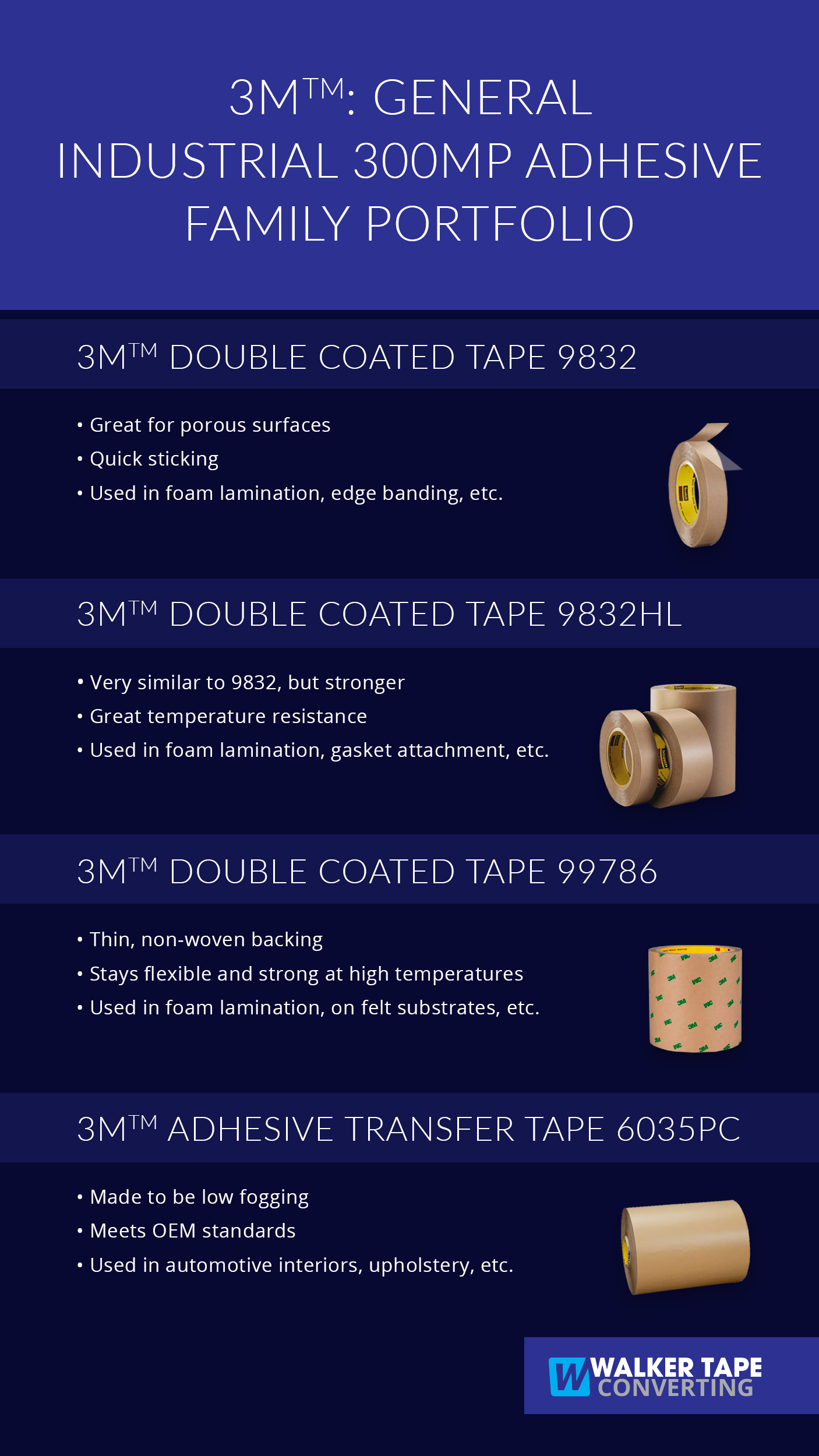

3M™ Double Coated Tape 9832

The first tape in this family that we’re going to cover is the 3M™ Double Coated 9832 tape. There are lot of things to love about this tape.

One of the biggest benefits of the 3M™ Double Coated 9832 is that it has quick stick results. The 3M™ 300MP High Tack Acrylic adhesive that is used on the tape is perfect if you’re looking for high initial adhesion. It is able to bond almost immediately.

Another benefit is that it is a great choice for porous surfaces. Porous surfaces have low-surface energy, so it can be difficult to get adhesives to stick to them. This tape is designed to stick to those surfaces with its quick stick bond.

This tape is also solvent-free. Meaning that it’s much more eco-friendly. Plus, there are no potentially hazardous fumes for you and your team members to worry about when working with it, especially in high heat.

Speaking of high heat, 3M™ Double Coated 9832 has also been made to have better temperature resistance. Whether it’s intense heat or temperatures below 0o, this tape will stand up to the test.

Generally, this tape is used for foam lamination, cabinet refacing, card holder mounting, edge banding, among other things.

Quick facts

- Great for porous surfaces

- Quick sticking

- Used in foam lamination, edge banding, etc.

3M™ Double Coated Tape 9832HL

The next tape is 3M™ Double Coated 9832HL. As you may be able to tell from its name, this tape is very similar to 3M™ Double Coated 9832. However, it has a very notable difference.

One of the biggest differences is that the liner used in this tape is thicker and heavier. But if that’s the main difference, why would someone want to use 9832HL over 9832?

There are a number of different benefits to having a thicker, heavier liner. The thicker liner can provide better moisture stability, which is perfect for projects that will be exposed to weather and water. The thicker liner is also helpful for when you need the tape to lay flat. The extra weight can help keep it from curling up, making it easier to work with.

This makes it a great choice for holding fabrics, foams, plywood, plastics, and wood.

Of course, 3M™ Double Coated 9832HL also has the benefits of regular 3M™ 9832, including being solvent-free and able to withstand intense-temperatures. The main difference is that it’s a bit more heavy duty.

3M™ Double Coated 9832HL is usually used in foam lamination and gasket attachment.

Quick Facts

- Very similar to 9832, but stronger

- Great temperature resistance

- Used in foam lamination, gasket attachment, etc.

3M™ Double Coated Tape 99786

The third member of the 3M™ 300MP Adhesive Family is 3M™ Double Coated 99786.

Like the others, 3M™ Double Coated 99786 is double-sided. However, this time the adhesive is on a thin, non-woven backing. This backing allows it to be very flexible and very strong. Plus, this thin backing stays strong, even in high temperatures.

All of that together makes this tape have better handling and dimensional stability in several different processes like slitting and die-cutting. As a result, it can be great for converting, making it ideal for custom tapes.

In general, 3M™ Double Coated 99786 is used on foam and felt substrates. It is a favorite for upholstery on things like ATVs and boats.

Quick Facts

- Thin, non-woven backing

- Stays flexible and strong at high temperatures

- Used in foam lamination, on felt substrates, etc.

3M™ Adhesive Transfer Tape 6035PC

The final tape we’re going to cover is 3M™ Adhesive Transfer Tape 6035PC.

This tape is rather different from the rest. Instead of just being a double coated tape, it’s a transfer tape. This means that it doesn’t have a backing or a carrier. You peel everything off, leaving only the adhesive.

Generally, transfer tapes are used for projects that require a thin product, like screens or windshields.

What makes 3M™ Adhesive Transfer Tape 6035PC so great is that it is designed to be very low fogging. This way, it meets OEM specifications for automotive interiors.

Not only that, but this tape also has high temperature resistance. So, it is a great choice for outdoor use, holding strong in hot and cold weather.

3M™ Adhesive Transfer Tape 6035PC is also a great choice for interior fabrics and panels. It is nice and thin, while holding the layers together with no problems.

One final benefit of 3M™ Adhesive Transfer Tape 6035PC is that it bonds well with most surfaces. As a result, it can be used just about anywhere, on just about any project.

Quick Facts

- Made to be low fogging

- Meets OEM standards

- Used in automotive interiors, upholstery, etc.

There you have it, the main members of the 3M™ 300MP Adhesive Family. Each of these tapes has its own benefits that may draw you to them for your next project.

Tapes like this are generally sold in large rolls, so you may worry about how you’ll fold it into your production process. They can be hard to work with and cutting them down takes valuable time. That’s where we at Walker Tape Converting come in.

We will work with you to determine the exact kind of tape that you will need for your project. Then we will help you figure out the best way to convert the tape to fit your needs.

We have the facilities and tools that are needed to convert tapes into exactly what you need. Each of the tapes in the 3M™ 300MP Adhesive Family are perfect for converting. So, no matter what your project is, we can help you get your hands on the adhesive you need.

Here at Walker Tape Converting, we have custom machines that allow us to take the tape you want and turn it into the tape you need. With die-cutting, slitting, and several other processes, we’re ready to work with you.

If you’re ready to get started, head to our contact page. There you can ask for a consultation, a quote, or even a sample of some tape.

We know that this may all seem like a lot of information to process. That’s why our team of experts is there and will be happy to work with you to get you what you need.