Having your tape die-cut to the desired size and shape can save you time and money.

If you’re buying a generic, stock-size roll of tape, and cutting it yourself to whatever sizes or shapes you need—or you’re already having your tapes die-cut by another converter—ask Walker Tape Converting for a quote for custom die cutting. Chances are we can save you time, and money.

Walker Tape Converting can die cut tape with a liner into whatever custom shape and size is needed for your application, whether it’s circles, rectangles, octagons, or something else entirely. Die cut tapes can make assembly and liner removal faster and easier.

Benefits

Automating the die-cutting process means tapes don’t need to be cut by hand or with a makeshift in-house machine, leading to significantly reduced labor and waste.

Walker Tape Converting also offers other efficiencies such as automated reordering, and stocking inventory to reduce lead times.

While the finished die-cut piece is more expensive per square inch than uncut tape, your overall cost will be much less thanks to reduced labor and waste. In fact, one Walker Tape Converting customer estimated their savings as more than $200,000 per year.

Process

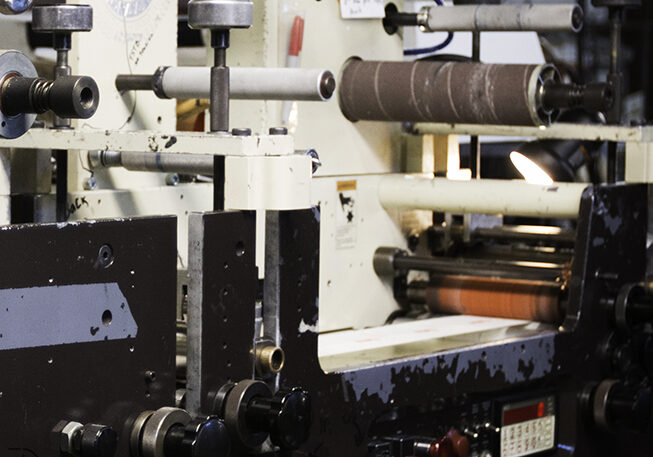

To begin the die cutting process, we create a steel shape, called a die, that is used with our machinery to cut the tape (similar to how a cookie cutter cuts dough).

We offer several cut options (including various levels of kiss cutting), depending on your needs:

Level 1: The die can cut all the way through the sheet, cutting the shapes out fully as individual pieces.

Level 2: The die can cut through just the top liner and adhesive but not through the bottom liner. This can leave the tape cut into shapes but still on one sheet or can leave the back liner longer than the tape to make the liner easier to remove.

Level 3: The die can cut through the top liner only in one section, cut through the top liner and adhesive in another section, and cut through the top liner, the adhesive, and the liner in the third section, making the top liner easier for end users to remove.

Level 4: The die can perforate the top liner, but not cut through it completely.

We can also leave custom impressions on a roll but not sheet them (embossing), if desired.

Once we have the material in stock, the finished order will be ready in 5 business days. For recurring orders, we offer to stock inventory.

Materials

Walker Tape Converting can die-cut nearly any tape—everything from masking tape, to duct tape, to double sided tape. What’s more, we’re not limited to existing types of tapes. If you have a unique application with two materials that need to be adhered, we can custom-create a differential tape and die cut that as well.

Featured Die Cutting Project

One of Walker Tape Converting’s customers makes silicone liners, which were spliced together with large tapes. Walker Tape Converting conducted a brief production study and found that switching to long, precut sheets could save this customer a significant amount of time and labor. Once the solution was implemented, the production study proved valid, saving the customer “game changing amounts of money.” In addition, Walker Tape Converting custom-designed a solution to laminate an adhesive magnetic material which could hold the tape while it cured, resulting in better production outcomes.

Die-Cutting: How It Works & How It Saves You Time and Money

There’s a pretty good chance that you’ve heard of die-cutting before. It’s used in several different industries. But just in case you aren’t familiar with it, die-cutting is using a premade piece to cut customized shapes out of a material. When it comes to tape, die-cutting is the best way to get the shape of…

Specialty Die Cutting for Medical Tapes

The medical industry is always changing and adapting. One thing that has stuck around for a little while in it is tape. Tape is used in so many different ways in the medical industry (which we’ll go over a bit later). When picking the right tape for your medical uses, there are a lot…

How Custom Tape Shapes Will Save You Money

We once walked into a potential customer’s shop and took a look at the process they had going on in the back. They were a company who had created some decorative magnets. They were paying people to cut out tape to fit the shape of the magnet. We watched the process for a little while and…

Getting a Quote is Fast and Easy

Filling out a short form is all it takes to get a fast and free quote. It will take just a few minutes to fill out the form; and many times we’ll get your quote back to you the same day.

New to die-cutting? Though die-cutting is generally not cost effective for smaller quantities, Walker Tape Converting offers much lower minimums for custom die cutting than many converters, so we encourage you to call and get a free quote.

Buying a custom die-cut from someone else? Get a quote from Walker Tape Converting. It’s free and easy, and we’ll even pay for your cost to switch converters (with a minimum contract).