All specialized fields are full of their own industry lingo. The adhesive industry is no exception. Since we want you to know exactly what to look for in a tape, we thought we would help you understand some of these terms.

So, let’s talk about a common one: wet-out.

This is a term that you’ll run into quite often with tapes and adhesives, so we’ll tell you what it means and why it matters.

What Does “Wet-Out” Mean?

To start off, let’s give a quick definition.

Wet-out in adhesives is how well the adhesive spreads out. Once the adhesive is placed on a surface, it starts to spread out. The amount that an adhesive can wet-out can be affected by a number of things including:

- The consistency of the adhesive

Thicker adhesives will wet-out more on specific surfaces than thinner ones will.

- The texture of the substrate it’s placed on

Rough and porous can stop wet-out either by creating barriers or absorbing the adhesive.

So, good wet-out means that the adhesive can spread out quite a bit. But what does that matter if you need the adhesive in a specific spot?

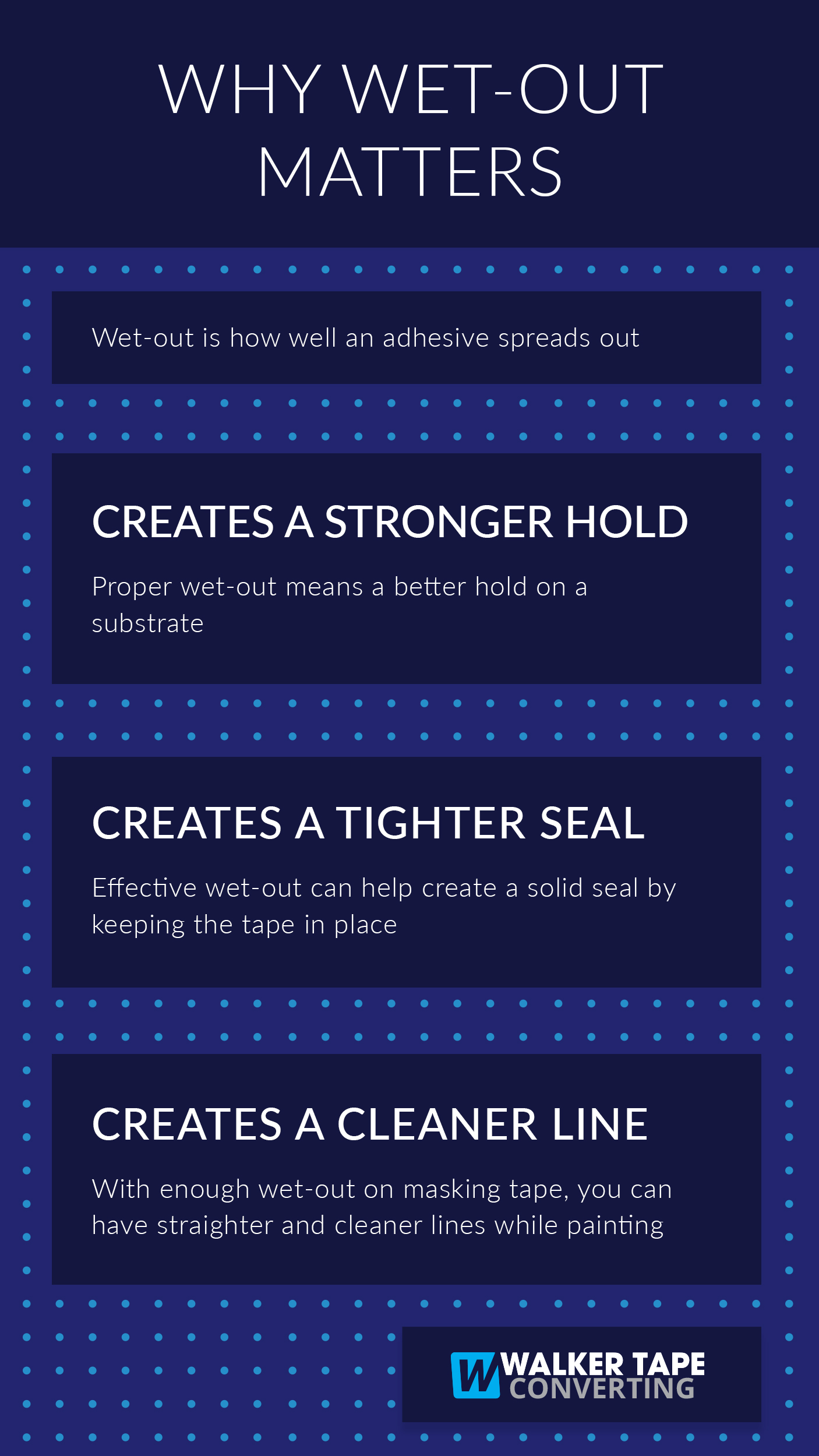

What Difference Does Good Wet-Out Make?

As long as an adhesive stays on a surface, why does it matter if it spreads out? Well, proper wet-out can mean the difference between an okay hold and a fantastic one.

When an adhesive is able to spread more efficiently, it covers more surface area. This means that there is more area for it to hold on to. Plus, if the adhesive doesn’t wet-out well, it can’t hold down the entire surface of the tape. Wet-out helps ensure that the tape lays flat, without the edges curling up.

Proper wet-out means that your adhesive will create:

- A stronger hold

- A tighter seal

- Cleaner lines

What Tapes Have Great Wet-Out?

There are mountains of tapes and adhesives that have excellent wet-out for just about any kind of surface. We don’t want you to have to sift through all of them, so here are just a couple of our favorites.

The first tape is 3M 468MP. The adhesive on this tape is thick, which allows for great wet-out on textured, metal, and plastic surfaces. This increases its strength and helps keep the edges from curling up.

Another benefit to this tape is that it’s not super tacky, which means it doesn’t grab hold right away. This may not seem like such a great feature at first, but it allows you to reposition the tape without losing any of the hold or wet-out.

If you’re looking for a tape with excellent wet-out that can be used for industrial purposes, 3M 468MP is the tape for you.

The other tape that has fantastic wet-out is Avery Dennison’s FM 2108. This tape is designed specifically for uneven surfaces. In order for this tape to hold on to those uneven substrates, the adhesive needs to wet-out quite a bit.

This wet-out capability also means that FM 2108 can form excellent bonds with high surface energy (HSE) and low surface energy (LSE) substrates. It can bond to just about anything!

For projects that have hard-to-stick-to, uneven surfaces, Avery Dennison’s FM 2108 could be the perfect choice.

If you want to learn more about how adhesive works, head to our blog, where we cover all things tape and adhesive.

If you have any questions, reach out to the team at Walker Tape Converting. We’re here to help you find the perfect adhesive solution for your project.