When choosing or designing an adhesive tape, most people think about everything but the liner. Most people don’t actually realize the impact this has on their application. Often, people don’t realize all of the problems caused by using the wrong liner until they experience using the correct liner and see the difference. Using the correct liner can save time, money, and frustration for you, your team, and/or the end users of your product.

To choose the correct liner, you must take both the properties of the adhesive and the properties of the liner into account. Different materials and chemicals react to each other differently. Think of markers as an example. If you use a general coloring marker on a plastic product, the color doesn’t hold. It easily wipes off. However, if you use a permanent marker, the color will stay on the plastic surface. A dry erase marker will only wipe off of certain surfaces like a dry erase board, glass, plastic, etc. but will not wipe off of paper for example. A permanent marker won’t wipe off of a dry erase board. A general coloring marker won’t even stay on a dry erase board. The difference in all of these scenarios is the chemicals and materials used to make the ink. The ink has to be specially designed for the surface and vice versa. You can think of adhesive tapes the same way. Certain adhesive tapes will not stick to certain liners because of the materials and chemicals used.

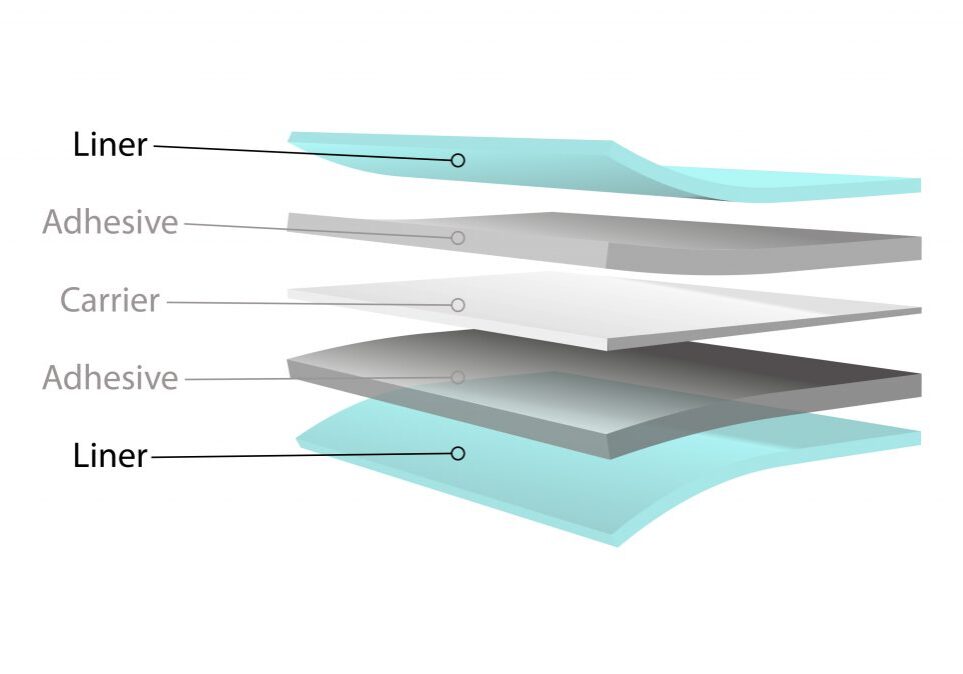

Because of this, using the wrong liner could mean the liner is either far too hard or far too easy to remove. Liners that are too hard to remove waste time in production and cause frustration for your employees and/or end users. Liners that are too easy to remove can fall off during transportation or storage and ruin your tape product. Sometimes we find that companies are using a tape with the correct adhesive and carrier, but the liner is incorrect and its causing major issues. When that’s happening, people may assume the tape is wrong and start over with a new product, not knowing that a simple change of liner could solve the issue.

Production settings are often the most obvious when it comes to liners saving time and money. In a production setting the goal is always to produce more in less time while maintaining excellent quality. If part of your production process includes removing a liner from a tape product, you need that to happen as quickly and efficiently as possible. In many applications in production, a paper liner can rip. This wastes time and often wastes product as well. Time and products cost money. Using a plastic liner in place of a paper liner can oftentimes save an incredible amount of time and money by removing this issue. Plastic liners are also thicker and therefore easier to peel in general, making your production process that much more efficient.

The liner is also an important consideration for tapes that will be die cut. There are a lot of liners that won’t hold up well during or after the die cutting process. Incorrect liners can cause structural and cosmetic issues in die cut tapes.

Many people assume that the tape converter they’re working with has thoughtfully designed their tape specifically for their application. However, many converters don’t have the knowledge or resources to ensure you’re getting the absolute best tape for your application. Many converters have stock liners that they use for all of their tapes. This puts their customers at a major disadvantage. At Walker Tape, things are different. We have a deep understanding of adhesive tapes and understand how to create tapes that maximize efficiency and reduce waste. We carefully select each part of your tape to ensure it’s best for your application, as well as your processes. We have the knowledge, resources, and supplier relationships to source and produce the best tapes on the market.

We have several types of liner in-house including:

- Polyester

- Kraft Paper

- Polyethylene

- Polypropylene

- Glassine

We also have relationships with the largest manufacturers in the world, and can source any type of liner needed. We even have access to liners for use with silicone adhesives. If you’ve worked with silicone adhesive tapes, you know that this is a rare commodity. There are actually only two companies in the entire world that produce liners that are compatible with silicone adhesives and we have a relationship with both of them.

We also have the ability to customize your liner. We can customize the color of your liner. Color options are limited depending on your volume, however. Do keep in mind that at a large enough volume, nothing is limited, but as smaller volumes, some options will be limited. We can also print your tape liners. Most paper liners can be printed. Depending on the volume of your order, we can also treat plastic liners to be printed on.

Whether you’re looking for a better solution for a current application, or hoping to create a new solution, look no further than Walker Tape Converting. We’d love to partner with you on your next project. Don’t hesitate to contact us today.