First Off, What Is a Differential Adhesive Tape?

Differentials are typically double-sided tapes that have two different adhesives on either side of a carrier. By carrier, of course, we simply mean the structural backing of the tape. Carriers for differential tapes can be made of various materials. That said, polyester carriers tend to be most common.

What Can Differentials Do for My Company?

- Create a better product for your customers

- Save you money on potential processing failures

- Keep you ahead of the competition

Simply put, every tape has specific strengths and limitations based on the type of adhesive they use. So, one of the best perks to using differentials is that you can combine the best attributes of two different adhesives.

For example, let’s say you’re dealing with dissimilar substrates. That is, you’re looking to bond different materials together. One material may be silicone foam, while the other is stainless steel. Using an acrylic-based adhesive tape may work well on the stainless steel, but it won’t stick as well to the silicone foam. The best tape for the silicone foam would definitely be a silicone-based adhesive.

Well, differential tapes are ideal for projects like this that deal with dissimilar substrates. With the above example, you could find the perfect solution with Avery Dennison’s FT 9302 SF differential option. As you can see in more detail below, it uses a general-purpose acrylic adhesive on one side and a silicone adhesive on the other.

Create a better product for your customers. With differentials, you have double the strengths to work with. This perk allows you to get more creative with your product line and offer your customers a better experience.

Save money on potential processing failures. We’ve often found differentials to be one of the easiest solutions to help companies boost their ROIs. Failures during production end up costing you in several ways: labor, cleanup time, and material waste. A lot of the time, differential solutions can make such failures few and far between because we can tailor each side of the tape for optimal performance.

Keep ahead of the competition. Frankly, differentials surprise most people outside of tape manufacturers. When looking for solutions, your competitors may end up unaware of differentials as an option to consider.

What Are Some Great Differential Options?

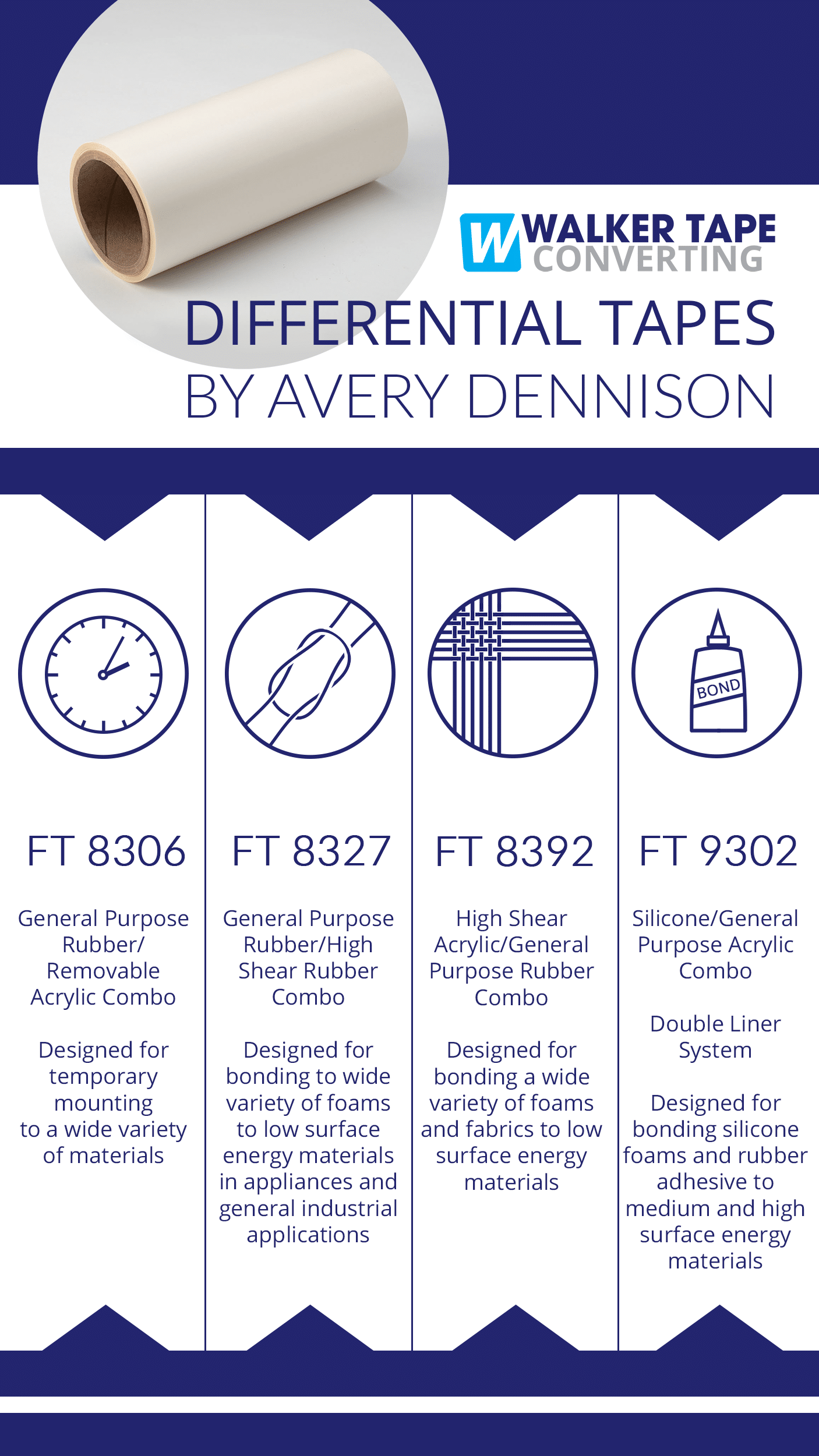

Below, we include standout differentials by Avery Dennison. These four options are all a part of their new Core Series™ Portfolio and include a generous two-year warranty. They also have excellent dimensional stability, making them easy to handle during production.

FT 8306

The FT 8306 combines the best strengths of a General-Purpose Rubber adhesive on one side and a Removable Acrylic adhesive on the other. It’s specifically designed for temporary mounting to a wide range of materials.

Benefits

- Temporary Removability

- Strong bond to wide array of materials

- Excellent foam bonding performance

- High tensile strength and tear resistance

- Great die-cutting performance that results in saving you money

Features

- Adhesive: Removable Acrylic

- Carrier: Polyester (PET)

- Adhesive: General Purpose Rubber

- Liner: #60 super calendared white kraft paper

- Liner Thickness: 3.5 mils

- Tape Thickness w/o Liner: 3.6 mils

- Max Service Temperature: 175°F

Common Applications Where Temporary Removability Is Required

- Removable/changeable foam gaskets

- Mounting promotional items

- General industrial

- Reclosable bags

- Polishing pads

- Core starting

- POP displays

- Graphics

- Signage

FT 8327

The FT 8327 packs the best traits of rubber adhesives together. One side uses a General-Purpose Rubber adhesive while the other uses a High Shear Rubber adhesive. This duo makes it ideal for bonding a variety of foams to low surface energy materials in appliances and general industrial applications.

Benefits

- Excellent foam bonding performance (especially to polyester urethane, polyether urethane, and polyethylene)

- Strong bond with a high shear strength to low surface energy materials

- High tensile strength and tear resistance

- Great die-cutting performance that results in saving you money

Features

- Adhesive: General Purpose Rubber

- Carrier: PET

- Adhesive: High Shear Rubber

- Liner: #80 super calendared white kraft paper

- Liner Thickness: 4.4 mils

- Tape Thickness w/o Liner: 4.6 mils

- Max Service Temperature: 175°F

Common Foam Applications

- Foam bonding for open cell PE & polyester urethane

- Sound Dampening

- Gasketing

- Sealing

FT 8392

The FT 8392 combines a High Shear Acrylic adhesive on one side to a General-Purpose Rubber adhesive on the other. It works great for bonding various foams and fabrics to low surface energy materials.

Benefits

- Good foam bonding performance

- Strong bond with high shear strength to low surface energy materials

- High heat and mold resistance (adhesives contain biocide)

Features

- Adhesive: High Shear Acrylic

- Carrier: PET

- Adhesive: General Purpose Rubber

- Liner: #80 super calendared white kraft paper

- Liner Thickness: 4.4 mils

- Tape Thickness w/o Liner: 3.8 mils

- Max Service Temperature: 175°F

Applications

- Foam bonding for open cell PE, polyether urethane, & polyester urethane

- Foam applications in automotive industry

FT 9302 SF

Like stated above, the FT 9302 SF uses a Silicone adhesive on one side and a General-Purpose Acrylic adhesive on the other. This differential features a double-liner system protecting both adhesives. It offers good adhesion to hard-to-bond low surface energy materials, such as silicone foams.

- Designed for bonding silicone foams and rubber adhesive to medium and high surface energy materials

Benefits

- Strong bond to silicone rubber, silicone sponge, and silicone-coated surfaces

- Strong bond to low surface energy materials

- High tensile strength with a double-liner system for easier processing, moisture stability, & lay flat properties

Features

- Adhesive: Silicone

- Carrier: PET

- Adhesive: General Purpose Acrylic

- Liner: #84 natural polycoated Kraft paper

- Liner: PET

- Total Liner Thickness: 7.6 mils

- Tape Thickness w/o Liner: 5.8 mils

- Max Service Temperature: 350°F

Applications

- Bonding to silicone sponge & silicone-coated surfaces

- General Industrial

- Automotive

The Perks of Working with Avery Dennison’s Core Series™ Portfolio and Walker Tape Converting

As an Advantage Converter with Avery Dennison, we can offer you the fastest quotes on these differentials and all tapes in their Core Series™ Portfolio. Plus, we offer free samples of any of these tapes and conveniently send them to you quickly.

Ready to see how differentials can boost your business? Request a free sample today.