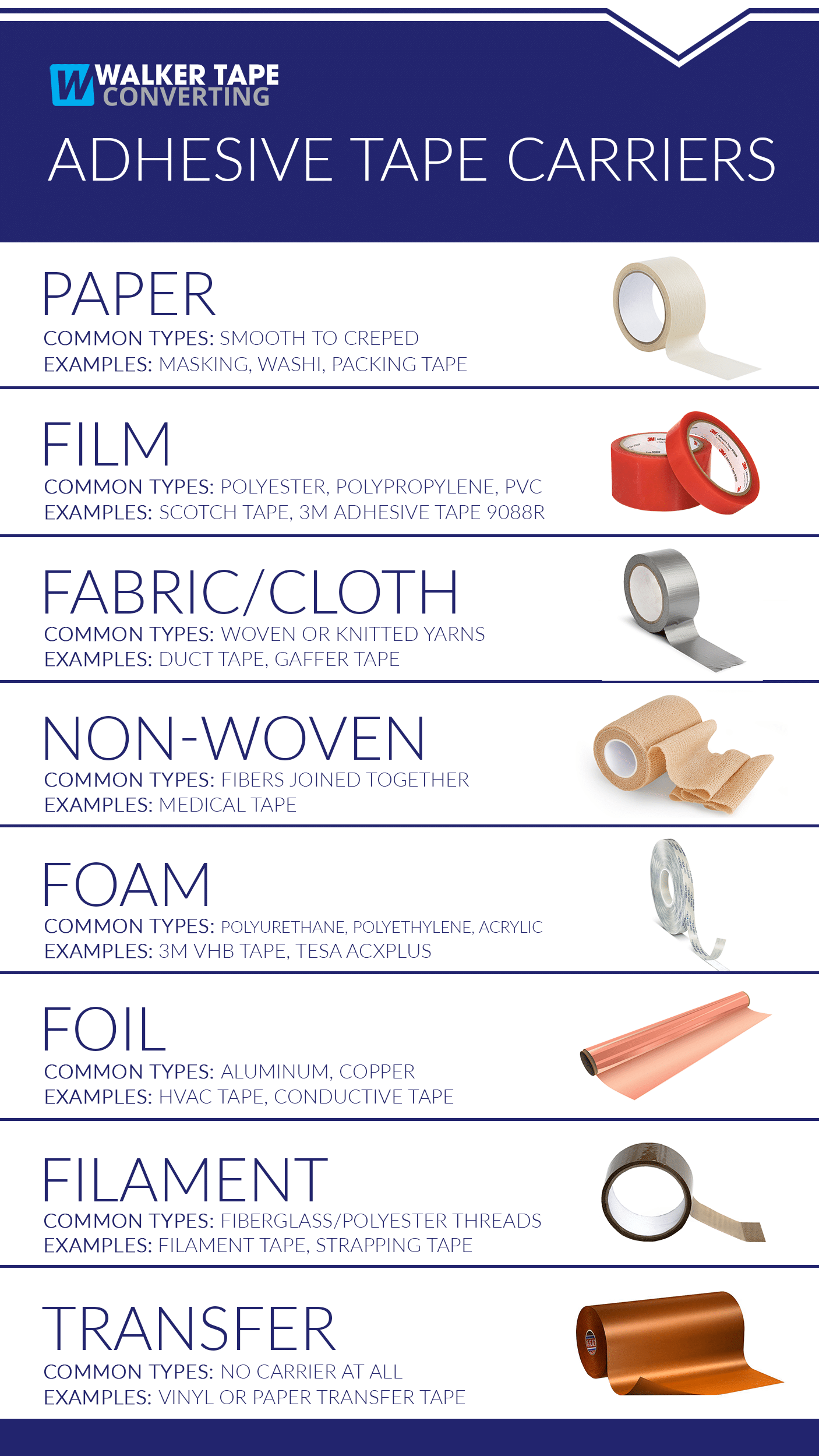

What’s an adhesive tape carrier?

An adhesive tape carrier is a thin, flexible material that carries the tape’s adhesive.

You’ll also see carriers called backings because they give tape structural support, kind of like a backbone. For example, the shiny plastic film of the tape sitting on your desk is that tape’s carrier.

Carriers impact a tape’s performance in various ways. In fact, they determine major characteristics of tape. This is one of the reasons why they even serve as a tape’s common name: foam tape, cloth tape, filament tape, foil tape, etc.

What are some examples and specific benefits to different types of adhesive tape carriers?

Paper Carriers

- Surface Protection

- Hand Tearable and Stretchable

- Conformable

- Stretchable

- Heat Resistant

Paper carriers come in a spectrum from smooth to creped choices. By creped, we mean a wrinkled texture. The more creped the paper carrier, the easier it is to tape on a curve. Common examples of tape with paper carriers include masking/painter’s tape, washi tape, and packing tape.

Surface Protection: This is why we make masking tape with paper carriers. They’re great for protecting surfaces underneath the tape.

Hand Tearable and Stretchable: Compared to all other carriers, paper takes the cake for how easy it is to tear by hand. While at the same time, it offers a good balance of tearability and stretchability.

It tears nicely across the width of the tape, making it more convenient to remove strips off a roll. But it also holds strong when pulling down the length of the tape. In fact, tape carriers can often be stretched up to 50% of its original length before breaking.

Conformable: Like mentioned above, the more you crepe a paper carrier, the more conformable it becomes.

Heat Resistant: You can find carriers on high-performance tapes that can withstand temperatures up to 356°F.

Film Carriers

- Dimensional Stability

- High Tear Resistance

- Suitable for Converting

- Heat Resistant

- Plasticizer Resistant

Film carriers you see most often are either polyester (PET), polypropylene, or PVC. Common examples of tape with plastic film carriers include Scotch Tape and 3M Adhesive Tape 9088R.

Dimensional Stability: Film tapes are known for their ability to maintain their original dimensions, even under various harsh conditions. This trait is thanks to the film carrier.

High Tear Resistance: Tied to their impressive dimension stability, film carriers are excellent at resisting tears or breaks.

Suitable for Converting: Film carriers are generally thought of as the easiest to die-cut, sheet, and so on.

Heat Resistant: This is specifically true for PET film carriers. If a high-performance tape with a film carrier has a high temperature rating, it’s most likely a PET film.

Plasticizer Resistant: Known in the tape word as a “plasticizer barrier.” Plasticizers are treatments to make something softer or more flexible.

These can be found in a lot of plastics across all industries. The problem is when these softening agents migrate into the tape and weaken the adhesive. So, if you’re working with materials that use these treatments, you’re going to want to consider using a tape with a film carrier.

Fabric/Cloth Carriers

- Conformable

- Durable

- Tear Resistant and Handa Tearable

- High Coating Weight

Typical fabric carriers come from woven or knitted yarns, such as cotton, viscose, or PET. Common examples include duct tape and gaffer tape.

Conformable: Fabric tapes can be every bit as form fitting as fabric clothing.

Durable: This is part of the reason why everyone knows about and uses duct tape.

Tear Resistant and Hand Tearable: Just like paper carriers, these tear nicely across the width of the tape, making it more convenient to remove strips off the roll. But they also hold strong when pulling down the length of the tape (known as tensile strength).

High Coating Weight: This is another reason why duct tape is so versatile. Fabric carriers can be coated with a lot of adhesive. This makes them great for all kinds of textured or rough surfaces.

Non-woven Carriers

- Conformable

- Durable, Absorbent, and Moisture Resistant

- Hand Tearable and Stretchable

- Washable and Recyclable

- Flame Retardant

Non-woven carriers are natural or synthetic fibers joined together either mechanically, thermally, or chemically. Common examples include medical tape for bandages and hospital electrodes.

Conformable: Just like paper and fabric carriers, non-wovens fit very well to match different shapes.

Durable, Absorbent, and Moisture Resistant: Considering that they’re used for bandages and hospital devices, it’s essential that they be able to hold their own against liquids.

Hand Tearable and Stretchable: Also like paper and fabric carriers, non-wovens strike a user-friendly balance. They’re both easy to tear when you need them to, yet they hold up when pulled without compromising the tape.

Washable and Recyclable: Non-wovens can be reused and recycled, which is very unique in the tape industry.

Flame Retardant: Yes, non-wovens can help make tape solutions that stop fires in their tracks.

Foam Carriers

- High Thickness

- Noise Dampening

- Compensates for Different Expansion Factors

- Levels Surfaces

Typical foam carriers are made of polyurethane, polyethylene, or acrylic. Common examples include 3M VHB Tape and tesa ACXplus.

High Thickness: When you think of foam tape, think padding. This helps improve a product’s quality in terms of durability and protection.

Noise Dampening: Also because of its thick padding, foam carriers work fantastically to dampen noises, vibrations, and buzzes.

Compensates for Different Expansion Factors: In temperature changes, materials expand and contract. Foam carriers are made to handle these fluctuations with ease.

Levels Surfaces: If you’re working with irregular or uneven surfaces, foam carriers provide a consistent leveling.

Foil Carriers

- Conformable

- Moisture, Age, Chemical, and Flame Resistant

- Electrically and Thermally Conductive

- Heat and Light Reflective

Usually when we’re dealing with foil carriers, they’re usually aluminum or copper. Common examples include HVAC tape and conductive tape.

Conformable: Ever wrap a potato in foil? It’s incredibly easy to do. You get this same performance from foil carriers in tapes.

Moisture, Age, Chemical, and Flame Resistant: Here’s a fun fact: instead of using duct tape, duct workers in HVAC use foil tapes. That’s because this carrier performs so well against moisture, aging, and exposure to chemicals and flames.

Electrically and Thermally Conductive: Foil carriers can hold a charge as well as conduct heat.

Heat and Light Reflective: They can also be used to create heat shields and improve the light performance in various products.

Filament Carriers

- Tear and Stretch Resistant

- Conformable

- Age and Chemical Resistant

What we mean by filaments are carriers that contain microscopic fiberglass or polyester threads. These tapes are commonly referred to simply as filament tape or strapping tape.

Tear and Stretch Resistant: Because filament carriers are reinforced with thousands of microscopic fibers, they’re incredibly resistant to tearing and stretching.

Conformable: This trait along with the above tear and stretch resistance is why filament carriers make such good strapping tapes.

Age and Chemical Resistant: The fiber reinforcements also make them last through tough conditions.

Transfer (No Carrier at all)

- Conformable

- Cost Efficient

- Customizable

- Very Thin

This may be a cheat. But since it’s also an option to have no carrier at all with tape, we figured we’d include it.

Conformable: Since there’s no carrier there at all, transfer tapes are easily the most conformable of all the carrier options listed here.

Cost Efficient: Also, going without a carrier means you save money that you’d otherwise spend on carrier material.

Customizable: Transfer tapes are so versatile, we’ve dedicated a blog to the topic. The title hopefully gets the point across: The Most Versatile Tape in the World.

Very Thin: Just a layer of adhesive is as thin as a tape can possibly be.

Considering our unique capabilities at Walker Tape Converting, we have decades of experience working with tapes with each of these carriers. Ask us for a free quote request today, and we’ll work with you to get the perfect carrier for the tape solution you need.