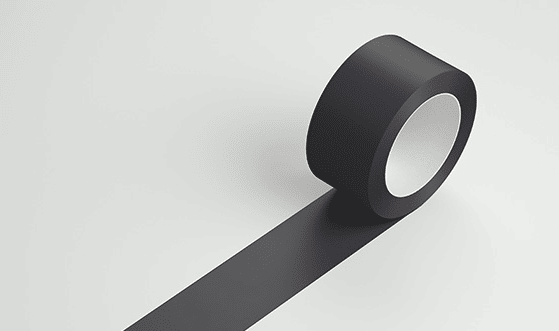

Heavy-duty tapes for any industrial application

All kinds of problems. All kinds of solutions.

Whether you need tapes for manufacturing, assembly, equipment maintenance, safety on the shop floor or job site, or the wide variety of other uses for industrial-grade tapes, Walker Tape has a solution. It's what we were built on. To ensure we design a tape that meets your needs, we consider what layers or surfaces (substrates) it interacts with, the variable environmental conditions, the production processes and much more.

Common industrial tape applications include:

Types of industrial tapes:

Strength & Durability

Bonds that won't break

In the industrial sector, tapes are exposed to a variety of challenges. Environment. Temperature. Pressure. Substrate surface. Longevity.

That's why it's vital for those bonds to hold fast, every time.

Some of our heavy-duty, double-sided tapes hold with such power that even metal will tear before those bonds will break. And in many circumstances, tape outperforms mechanical fasteners and glue.

Precision

Custom machinery to meet your needs & challenges

Our story is rooted in machinery innovations. There’s a dizzying amount of detail that goes into what makes a certain tape the right tape for a project. It takes the best machinery with the right capabilities to provide precisely the adhesive, carrier, liner, and dimensions that work best for your application. Our machines are built to convert to those precise specifications.

Along with precision comes minimal waste. Our machinery uses state-of-the-art technologies that help to minimize waste, which in turn maximizes your ROI. We’ve even had customers tell us that our machines cut waste in half by comparison to other converters they’ve worked with.

The Walker Difference

One converter, vast possibilities

Our cababilities

Walker's power of possibilities

With our decades of experience, we know tape. Here are some of the capabilities and expertise we use to craft the perfect product for you.

Need a custom shape and size? No problem. We can die cut tape with a liner into whatever custom shape and size you need.

If the existing tape liner is too flimsy for your application, rips easily, or doesn’t come well, we can replace it by laminating another liner in place.

Our in-house design team can design custom packaging for your retail products. Need a logo? We can help with that, too.

We can quickly and easily replace the liner that came stock on your tape with a more suitable material for the job at hand.

Need tape cut to a custom length and width? We have a customized sheeter that allows us to cut any length and width up to 48 inches.

We offer three slitting options: crush-cut, razor and baloney. Ideal for customers who require a variety of widths.

Contact us today!

Getting a quote is fast & Easy

Filling out a short form is all it takes to get a fast and free quote. It will take just a few minutes to fill out the form; and typically we're able to get your quote back to you within the same day. Even if you're happy with your current converter, ask us for a free quote. It's hassle free and sure to surprise you. Our better prices and faster lead times make happy customers even happier. We’ll even pay for your cost to switch converters (with a minimum contract).